The technological innovation and development of artificial leather materials in the production of automotive steering wheels are mainly reflected in the following aspects:

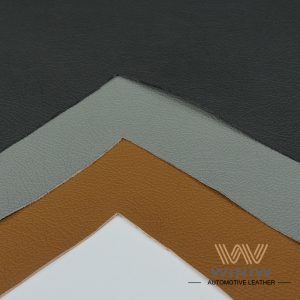

Improved material durability and tactility: Toyota Synthetic Corporation, in collaboration with Salem Corporation, has developed a synthetic leather for steering wheels, with a focus on improving the surface coating to make it more tactile and durable. This synthetic leather performs well in chemical composition penetration tests, with high stain resistance and intermolecular bonding, allowing it to maintain good performance under impact and friction loads.

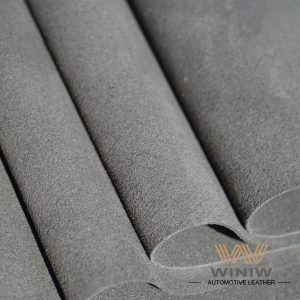

Anti-bacterial and anti-virus treatment technology: Tianshou has developed an ecological steering wheel microfibre leather with 99.99% anti-bacterial rate. This material not only possesses good dirt, scratch and weathering resistance, but also instantly sterilises and kills toxins, safeguarding the health and safety of consumers on the road. This technology has been adopted by Geely, Dongfeng Motor and other car companies, and is expected to lead the future development of antibacterial technology for automotive interiors.

Environmental protection and sustainability: With the awareness of environmental protection

Environmental protection and sustainability: With the increasing awareness of environmental protection, new imitation leather materials such as water-based microfibre leather are attracting attention due to their fully water-based environmental protection characteristics and better resilience. These materials not only reduce the use of chemical treatment agents, but also meet the high safety requirements of natural leather in the EU and other regions.

Digital Cutting.

Digital cutting technology: The use of digital leather cutting technology significantly increases material utilisation and reduces production costs. By optimising the utilisation of expensive leather materials, the steering wheel manufacturing process is made more streamlined and sustainable.

Modular design: Yanfeng introduced the ClickRim concept for modular steering wheels, which allows for individually customised steering wheel surface materials, including fabric, leather, faux leather, etc., through interchangeable segments, thus meeting specific needs and reducing manufacturing time.

Bio-based polyurethane (PU) leather: New bio-based PU leather materials are also making inroads in automotive interior design. These materials have high mechanical properties and chemical resistance, making them suitable for use in components requiring high durability, such as steering wheels

.

These technological innovations and developments not only enhance the durability and comfort of steering wheels, but also promote the development of automotive interior materials in the direction of more environmentally friendly and healthier.