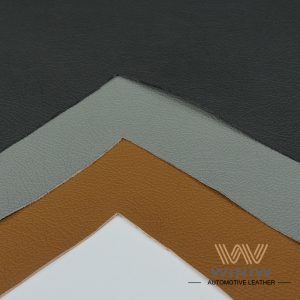

In industries where equipment and products face relentless abuse think oil rigs, emergency vehicles, or high-traffic public spaces material failure isn t an option. Microfiber leather, engineered to thrive under punishment, has become the ??#1 choice?? for manufacturers tired of compromises. WINIW International Co., Ltd, a ??Top 5 Global Supplier??, breaks down why this material is rewriting the rules of industrial durability.

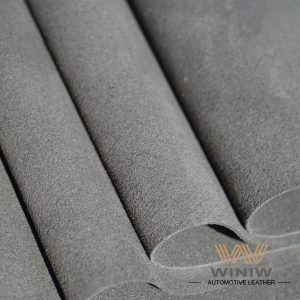

??1. The 200,000-Rub Benchmark: Where Others Fail??

Real leather starts cracking at 10,000 abrasion cycles. Cheap PU/PVC split at 20,000. Microfiber leather? It laughs at ??200,000+ Martindale cycles?? proven in:

- ??Firefighter gear?? surviving debris and friction during rescues.

- ??Airport security scanners?? enduring millions of luggage scrapes.

??2. Extreme Temperatures? No Sweat.??

From -30 C Arctic truck cabins to 120 C factory floors, microfiber leather stays flexible and intact. Competitors crack or melt. Real-world wins:

- ??EV battery covers?? resisting thermal spikes.

- ??Refrigerated food packaging?? without brittleness.

??3. Chemical Warfare? Bring It On.??

Spilled diesel, bleach, or hydraulic fluid? Microfiber leather shrugs it off. Compare that to real leather (rotting) or PVC (staining). Used in:

- ??Chemical plant seating?? exposed to acidic fumes.

- ??Ambulance interiors?? sanitized daily with harsh disinfectants.

??4. UV Armor: 5+ Years Without Fading??

After 1,500+ hours of UV testing (equivalent to 5 years in direct sun), microfiber leather retains ??95% color and texture??. Real leather cracks in 2 years. Applications:

- ??Solar farm control panels?? in desert climates.

- ??Outdoor military equipment?? needing stealthy durability.

??5. The 10-Year Lifespan: Slash Costs, Boost ROI??

While competitors require replacements every 2�C3 years, mikrofiber læder delivers ??decade-long performance?? med:

- ??Zero hydrolysis?? in humidity (no layer separation).

- ??50,000+ flex cycles?? without creasing (per SATRA TM-31).

??Why WINIW? Beyond Durability??

- ??Certified for Crisis??: Meets IATF 16949 (automotive), I 455 (medical), and UL 94 flame resistance.

- ??Custom-Built??: Add anti-microbial coatings, anti-static layers, or RFID embedding.

- ??Eco-Forward??: 35% recycled content + closed-loop water systems reduce waste.

??Proven in the Trenches??

- ??Mining Industry??: Conveyor belts lasting 7+ years in abrasive, dusty mines.

- ??Public Transit??: Train seats surviving 10 million passengers without wear.

- ??Marine Sector??: Boat upholstery resisting saltwater corrosion and UV damage.

??Engineer Unbreakable Products with WINIW??

As a ??Top 5 Supplier??, we don t just sell materials we eliminate your downtime, recalls, and replacement costs. ??Request a FREE stress-test report?? or sample today. See why industries under the harshest conditions refuse to settle for less.