As a professional Leather Car Seats Factory serving the global auto industry, WINIW specializes in R&D and mass production of high-end genuine leather car seats—backed by 25+ years of leather craftsmanship, a 100,000+㎡ ISO 16949-certified production base, and automated lines (CNC cutting, precision stitching, foam molding) to meet B-end partners’ demands (auto OEMs, luxury 4S dealerships, customization studios, fleet operators).

OurThe core advantage of leather seats directly hits the pain points of the market, luxury or practicality:

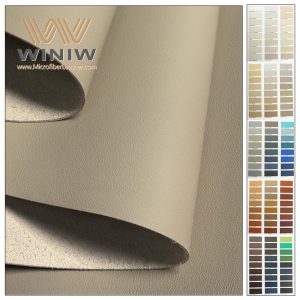

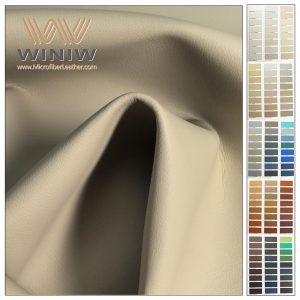

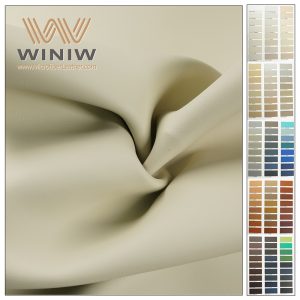

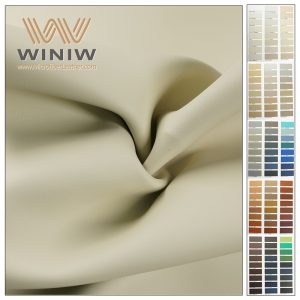

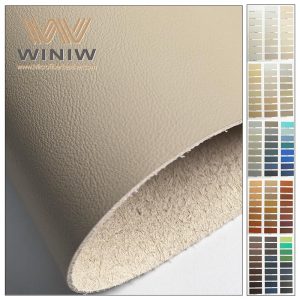

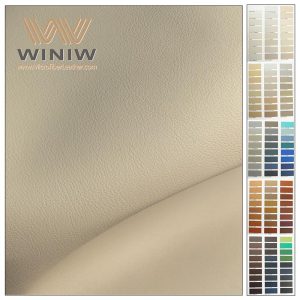

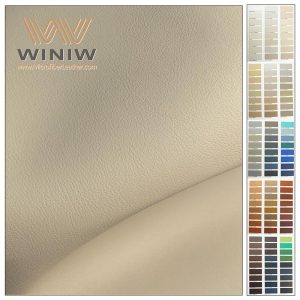

- Premium Genuine Leather Selection: Adopts full-grain leather (top 10% of cowhide) and nappa leather (softened via 12-stage tanning), passing 100,000+ friction tests (scratch-resistant, no peeling for 5+ години) и 800+ hours of UV aging tests (no fading under long-term sunlight). The leather is treated with eco-friendly waterproof coatings—spills like coffee or rain can be wiped clean in 30 seconds, avoiding permanent stains.

- Safety & Comfort Engineering: Complies with global automotive safety standards: airbag-compatible stitching (ensures 0.1s fast deployment), high-density memory foam cushions (50,000+ compression tests, maintains support to reduce driving fatigue), and optional heating/cooling modules (even temperature distribution, low energy consumption for new energy vehicles). Ergonomic backrest contours fit human spine curves, with adjustable lumbar support for long drives.

- Wide Model Adaptability: In-stock templates for 2,500+ popular models (sedans, SUVs, sports cars, commercial vans—e.g., BMW, Mercedes-Benz, Toyota), с <3mm fit precision (no gap between seat and vehicle body). Custom designs support rare/modified cars (based on 3D seat scans) and brand customization (logo embossing on headrests, color matching to vehicle interior VI).